Battery packaging includes the casing of cells, packaging of modules, and transportation packaging. The packaging material varies based on the type of battery. For instance, polypropylene is used in lead-acid battery casings, while aluminum is used as a packaging material for lithium-ion batteries. Batteries are classified as dangerous goods for transportation due to their volatile nature and are thus subject to various packaging and transportation regulations based on the mode of transport.

Request a report sample @ http://bit.ly/2Wt5CoC

Batteries are prone to chemical hazards, electrical hazards, and failure of battery management system. This includes electrolyte leakage, heat production, venting of gases, fire, and explosions. Therefore, battery casing and packaging is critical in the manufacturing of batteries.

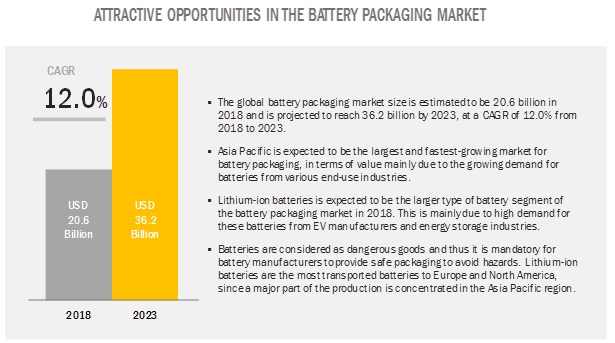

The battery market is growing rapidly due to demand from end-use industries such as energy storage and automotive, among others. MarketsandMarkets expects the Battery Packaging Market to grow from USD 20.6 billion in 2018 to USD 36.2 billion by 2023, at a Compound Annual Growth Rate (CAGR) of 12.0% during the forecast period.

Based on type of battery, lithium-ion battery packaging is estimated to be the largest segment of the battery packaging market in 2018. In terms of value, it is estimated to account for largest share during the forecast period.

The world is mobilizing itself towards a society dominated by sustainable energy and sustainable transport. Use of alternative sources of energy and electric vehicles to control the ever-increasing carbon footprint are some of the efforts undertaken to achieve this goal. Harnessing alternative energy requires storage of this energy, such as in the form of a battery. This is leading to the increasing production and transportation of batteries globally.

The cell & pack packaging segment is estimated to account for the largest share, in terms of value, of the battery packaging market during the forecast period. Significant capital investments are being made by leading lithium-ion battery manufacturers globally.

For instance, most leading Asian battery manufacturers, such as Samsung, LG, SK Innovation, and GS Yuasa, have planned investments in various parts of Europe (Poland, Hungary). In 2018, Tesla identified 2 new strategic locations to establish lithium-ion battery plants, one in Europe, and the other in Shanghai. All these factors are resulting in the increasing demand for batteries, which is expected to drive the market for battery packaging during the forecast period.

In terms of geographic coverage, the battery packaging market has been segmented into 5 regions, namely, North America, Asia Pacific (APAC), Europe, the Middle East and Africa (MEA), and South America., APAC is expected to record the highest growth rate during the forecast period, due to the presence of leading battery manufacturers in this geography.

Download PDF Brochure @ http://bit.ly/2WtA6XE

This region is home to some of the leading battery manufacturers, including Panasonic, Samsung, GS Yuasa, Exide, and LG, among others. The presence of these large manufacturers has resulted in increased production and transportation of batteries from this region. This is driving the battery packaging market in this region.

Reference:

https://www.marketsandmarkets.com/Market-Reports/battery-packaging-market-140916712.html

For more Info Visit Blog: https://chemicalsresearchmarket.wordpress.com/blog/

Log in with Facebook

Log in with Facebook