Table of ContentsSilicone Roofing MythsElastomeric Roof CoatingsHow Much Does Roof Coating Cost Per Square FootWhite Elastomeric Roof Coating

They need more product to accomplish the desired dry film density, making them less economical than other elastomeric coverings. They can also be challenging to spray and hard on application equipment. Silicone roofing finishings are the preferred choice when it concerns UV protection and resistance to ponding water. They deteriorate much slower than other coatings without ending up being breakable or hard.

This means less product is required to achieve the required dry film density. Silicone finishings are developed by including solvents and a driver to a silicone base. Offered in white, gray, or tan, how much to fix a roof silicone can be set up on a range of roofing system types including metal, modified bitumen, single-ply, EPDM, built-up roofing systems, and spray polyurethane foam.

Silicones attract dirt rather easily. This means the system will gradually lose reflectivity over time if not cleaned occasionally. They are also exceptionally slippery when wetness is present. Resistance to tearing is another inherent weakness. If pedestrian traffic is anticipated on the roofing, we extremely advise integrating roofing granules into the system.

When it pertains to strength, toughness, and adhesion, urethane roofing system finishings are 2nd to none. Compared to other finishes, they are more impact-resistant and are much better suited to manage pedestrian traffic. They are also strong enough to sustain the natural expansion and contraction (thermal motion) of roofing system structures and the unfavorable impacts of ponding water.

How Much Does It Cost To Coat Or Seal A Roof?

Aliphatics are normally utilized as top http://jaidenwnyq174.theburnward.com/elastomeric-roof-coatings coat, as they are more UV stable, resistant to dirt pick-up, and have remarkable color retention. Aromatics are less expensive however not rather as UV stable. They are primarily utilized as a foundation finish in a lot of roof restoration systems. Both types can be spray or roll-applied, with a lot of system specs needing several coats at a rate of 1.5 gallons per 100 square feet.

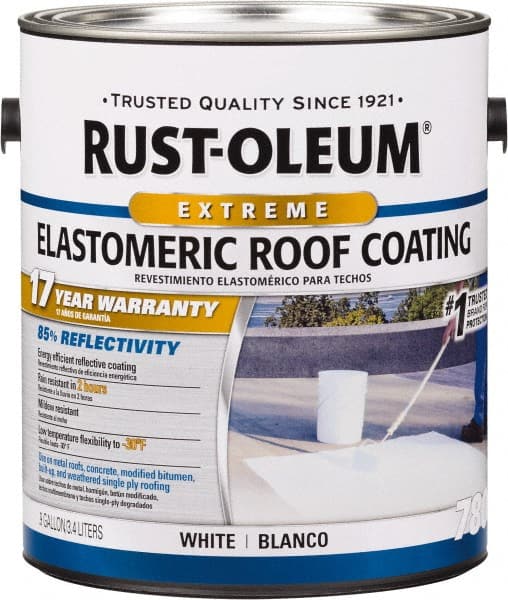

Elastomeric Roof Coating

Elastomeric Roof Coating

It's likewise worth discussing that urethanes are a moisture-cure finishing, indicating they are constantly curingeven in the pail. Every commercial roofing is various. That's why it's crucial to examine particular physical residential or commercial properties of a covering to guarantee its suitability in a particular roof environment. Each property listed below, along with other technical data, can be discovered in the producer's product information sheets.

A lot of elastomeric coverings typically measure anywhere between 250-900%. The higher the elongation value, the more suited a finishing is to withstand the normal growth and contraction of a roof structure without breaking, thinning, or removing. Tensile strength is the quantity of pressure a product can withstand before it breaks.

Elongation and tensile strength are carefully related but in an inverted direction. As one increases, the other decreases. The very best commercial roof finishing solutions balance the two homes to provide a strong, long lasting membrane that can properly extend and move with roof surface areas. Permeability, or perm score, is the state or quality of a product or membrane that triggers it to allow liquids or gases to go through it.

Quick Reference: Types Of Roof Coatings

Can You Walk On Elastomeric Roof Coating?

Can You Walk On Elastomeric Roof Coating?

For instance, acrylics have a high perm rating, indicating they are really breathable. Silicones, on the other hand, have a lower perm rating implying they have remarkable resistance to moisture transmission. It is very important to keep in mind that higher permeability does not correspond to inferior weather resistance. Reflectivity determines the amount in which a material can reflect light.

Unlike traditional, dark-colored roofing products, white roofing system finishing systems reflect 80-90% of the sun's energy back into the atmospheresignificantly decreasing the danger of heat gain throughout the roof structure. Emissivity describes a material's ability to launch absorbed heat. This home is normally represented as a decimal between 0 and 1, with 0.65 being thought about perfect for an elastomeric roofing coating.

Solids by volume is the measure of how much solid material will remain after a compound has actually dried. Understanding this home is important in order to correctly attain the required dry film thickness specified for certain finishing systems. While it has no bearing on the efficiency of a covering, this specific property is definitely worth some consideration.

For a complete introduction of the physical residential or commercial properties for American WeatherStar products, click on this link to download our complete roof finishing comparison chart. Ultimately, the performance of a business roof covering depends on a variety of elements. Each chemistry has its own distinct set of strengths and weaknesses. Things like roofing type, age, ecological concerns, visual appeals, and more must be considered prior to picking a suitable, long-term service.

Silicone And Acrylic Roof Coatings

In the commercial roofing worldand particularly in our restoration/revitalization specialty areawe use a lot of technical terms that we understand our consumers might not recognize with. This not surprisingly results in a lot of concerns, and it's our goal to educate the structure owners and managers we deal with as we bring new life to old, exhausted roofings.

What Is & How To Apply Elastomeric Roof Coating

What Is & How To Apply Elastomeric Roof Coating

While there tends to be some difference in the market regarding what particular roof finishes and products qualify as "elastomeric," the meaning of this term is quite easy. It describes substances that are elastomers, or that have elastic residential or commercial properties. Simply put, elastomeric materials stretch and can return to their initial measurements after doing sothink of an elastic band, and you'll have the ideal idea.

They are extremely protective against severe weather condition, UV light from the sun, and even foot traffic on your roofing system. The kind of elastomeric coating that's most suitable for your business structure's roofing system residential roofing specialists will depend on what products it was originally made from. Professional roofing specialists like us will work with you to assist you pick the best-performing finish for your unique roofing.

https://www.youtube.com/embed/prJIQ-5U_PU

Elastomeric roof finishes are developed to help stop leakages in aging roof systems made from a range of materials, like metal, layered asphalt, single-ply membranes, and more. When effectively applied by experts, these restorative finishings can seal bothersome joints and create a 100% leak-proof barrier throughout the surface area of your roofing.

Log in with Facebook

Log in with Facebook