A polyester material is used due to the fact that it will stretch with the finishings. (Fiberglas fabric is not recommended.) Fabric is generally cut to extend three inches beyond the fixed location in all directions. The finish is applied to the roof surface and the material is immediately pushed into the wet surface area.

![]() Uniflex Elastomeric Coating System For Metal Roofs

Uniflex Elastomeric Coating System For Metal Roofs

If your roofing has stucco parapets, analyze them for fractures along the sides and top. These areas frequently permit water to enter the wall and can trigger blisters and wrinkles in the roofing surface area. Repair work with Elastek 103 Crack & Joint Sealant. If you do not have parapets, examine the metal drip edge for a tight seal with the roofing membrane.

Roof Coatings, Roof Paints And Waterproof Roof Coatings

Roof Coatings, Roof Paints And Waterproof Roof Coatings

Elastomeric Reflective Roof Coating

Elastomeric Reflective Roof Coating

Apply finish when the roofing is dry and the sealant has actually set. You will be using a 9-inch heavy-duty frame, -inch paint roller for spreading covering on roofing system or 1-1/4-inch roller for dipping in pail, and a 5to-6-foot extension pole. Use a 3/4-inch roller with basecoats and emulsions. Map out your roof and make each pail fill that location.

You Could Check Here:

A low-cost 3-inch or 4-inch brush must be used to reach locations not possible with a roller. Utilize a stiff paintbrush for applying 103 Crack & Joint Sealant. Topcoat must always be applied in a really thick coat, to accomplish a rate of 100 sq. ft. per gallon, and a dry coating density of 10 mils.

Coatings are used with a minimum of working the product for an optimum density. Work right from the pail, dipping the roller or soak roof and spread. Give scupper and ponding areas several additional coats for included defense. Enable each coat to dry before recoating. In cool weather, one coat a day is the maximum; 2 might be possible in the summertime.

Kool Seal 10 Year Elastomeric Roof Coating

ft. per gallon, or a minimum of 20 mils dry covering. If two total overcoats are not applied, always apply 2 thick coats to issue locations such as scuppers, drain areas, ponding locations, joints, and repaired areas. Avoid utilizing Elastek Solar Magic or The Shield on ponding roofings. Clean skin and tools without delay with water.

These are the wires connecting the roof venting fan. I clipped them simply above the blue splice joints. Roofing system vent gotten rid of and cleaned up. After clipping the wire and getting rid of the vent, I tidied up any remaining goop and got my very first great take a look at the roofing system frame. It's metal! 1 1/2 inches thick.

Some RV roofings are framed with wood, others have metal framing. I had no concept what remained in my camper till this point. Not too delighted about the amount of rust on it, however ideally it is still structurally sound! I removed some rust and made a big mess inside the restroom.

Oops. Possibly I ought to have put a tarpaulin down initially. My final objective of the day was to get the fridge vent cover off. I saw RV sealant blobs at four points on the cover so assumed there must be screws under them. I pried them up and discovered Phillips screw heads.

Exposing the screws in the refrigerator vent cap. Removing old Recreational Vehicle roofing system finish on top of fridge vent cap I also saw that there was a coat of Recreational Vehicle roofing covering over the vent cap. These finishes are painted on with a brush so plainly whoever did this finish simply blobbed in on top of everything.

Hop Over To This Web-Site: https://www.dcroofingarizona.com/residential/roof-coating-tucson/elastomeric-roof-coatings/

Lifting off the cover of the refrigerator roofing vent. When the cap is off it's more of the very same. Removing more rubber and scraping off Recreational Vehicle roofing system sealant and old caulk. Get comfy due to the fact that this sucker has 32 screws in it! Ugh. Scraping lap sealant and caulk from screw heads.

How To Apply Elastomeric Paint (With Pictures)

Some screws will be too rusted and need pliers to get rid of. Prying off the fridge roofing vent after all screws are removed. (and the tools utilized.) Nearly every screw remained in sufficient condition to get rid of with a socket chauffeur, however a couple were too rusty and required to be twisted out with vice grip pliers.

I peeled off the remaining rubber roofing system from under the flange and then removed the old putty underneath. I'll clean it better if and when I choose to recycle it. Appears like it's in decent shape so I probably will. Scraping off the old putty from the flange of the fridge roofing vent.

Tips For Applying Your Elastomeric Roof Coating

Tips For Applying Your Elastomeric Roof Coating

I scraped the framing inside the opening and discovered that the framing around the fridge vent is made of wood (unlike the metal frame around the roofing system vent.) Then I covered it up with a scrap of wood so I wouldn't drop any scrap into the fins on the back of the fridge! Here's a peek inside the fridge vent.

Technical Data Sheet Elastomeric Roof Coating

Technical Data Sheet Elastomeric Roof Coating

That's as far as I got on day 1 after about 5 hours of lazy work. Not a bad start. I likewise saw this incredible slime mold growing in the mulch under the camper. If you've never ever seen a slime mold, have a look at some time lapses of them growing! They are freaking incredible! A slime mold under the camper! Now continue to step 2 when I eliminate the rest of the roofing system fixtures!.

https://www.youtube.com/embed/RpCzsQ7HUog

?.!!.

Log in with Facebook

Log in with Facebook

What Every Homeowner Should Know About Roof Inspection

What Every Homeowner Should Know About Roof Inspection Should I Get A Roof Inspection?

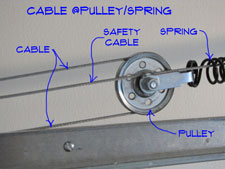

Should I Get A Roof Inspection? Garage Door Repairs For Broken Cables

Garage Door Repairs For Broken Cables Broken Garage Door Cable? Here's What To Do

Broken Garage Door Cable? Here's What To Do Garage Door Spring Repairs And Who To Call

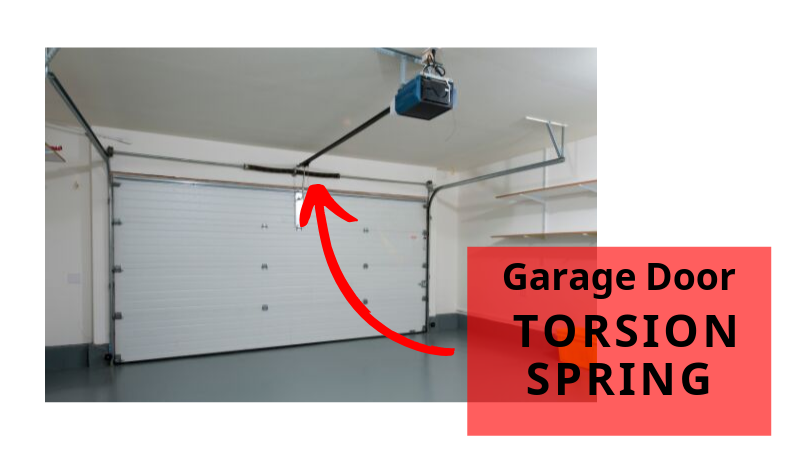

Garage Door Spring Repairs And Who To Call Garage Door Springs - What To Know Before Attempting To Repair

Garage Door Springs - What To Know Before Attempting To Repair Garage Door Torsion And Extension Spring Repair

Garage Door Torsion And Extension Spring Repair How To Replace & Install Garage Door Springs

How To Replace & Install Garage Door Springs Do I Need To Replace Both Garage Door Springs?

Do I Need To Replace Both Garage Door Springs?