In the previous article I wrote a common problem with stamping dies: mold failure. So here I will introduce you to this aspect of maintenance. The cost of stamping production is high. Usually the mold cost is 1/5-1/4 of the total cost of the part. This is because, in addition to the difficulty in manufacturing the mold and the high cost. The cost of mold repair and sharpening maintenance after putting into production is also high, and the original cost of the mold only accounts for about 40% of the total mold cost. Therefore, timely repair of the mold to prevent mold damage can greatly reduce the cost of stamping production. After the mold is damaged, there is a question of maintenance and scrapping. Generally speaking.

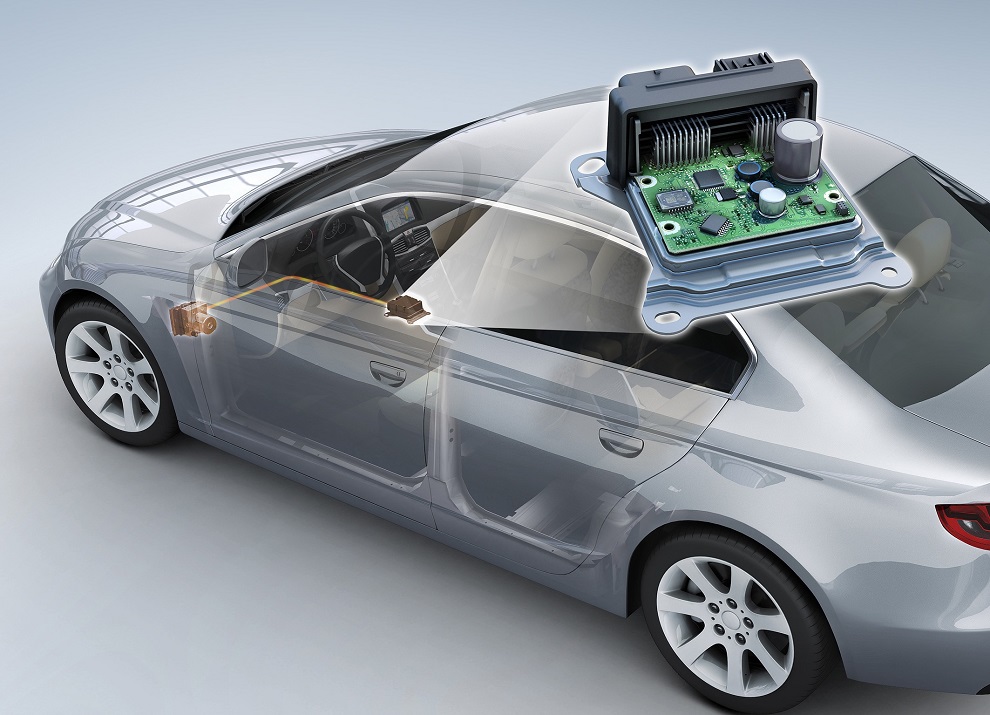

Unnatural wear of stamping dies, such as damage to non-critical parts. And the small punch is broken, the punch is thick and short, the concave template is cracked, and the cutting edge is cracked. Most of them can be restored to normal condition by repairing and re-commissioned into stamping production. but. When the key parts of the mold are seriously damaged, sometimes the convex and concave molds are damaged at the same time.The one-time repair cost Plastic Injection Molded Automotive Parts exceeds 70% of the original cost of the die, or the mold life is near. The meaning of maintenance is not great. At this time, the scrap mold should be considered: except for the large mold and the continuous mold with complicated structure.

When the mold repair technology is too complicated and the cost of mold repair is too large, the difficulty will inevitably make the maintenance period too long, which will seriously affect the normal production of stamping. It is necessary to choose to scrap the scrap beforehand and remanufacture the mold. Under normal conditions, the main failure mode of the die is excessive wear. Delivered from the manufacture of new molds. Until the burrs of the punched parts exceed the standard, the size and shape accuracy of the parts are too poor, and the mold can no longer be repaired or no repair value at all, the mold can only be scrapped. From the time the new mold is put into use to the end of the scrap. It usually takes many repairs and sharpening. I hope my summary is useful to everyone.

Log in with Facebook

Log in with Facebook