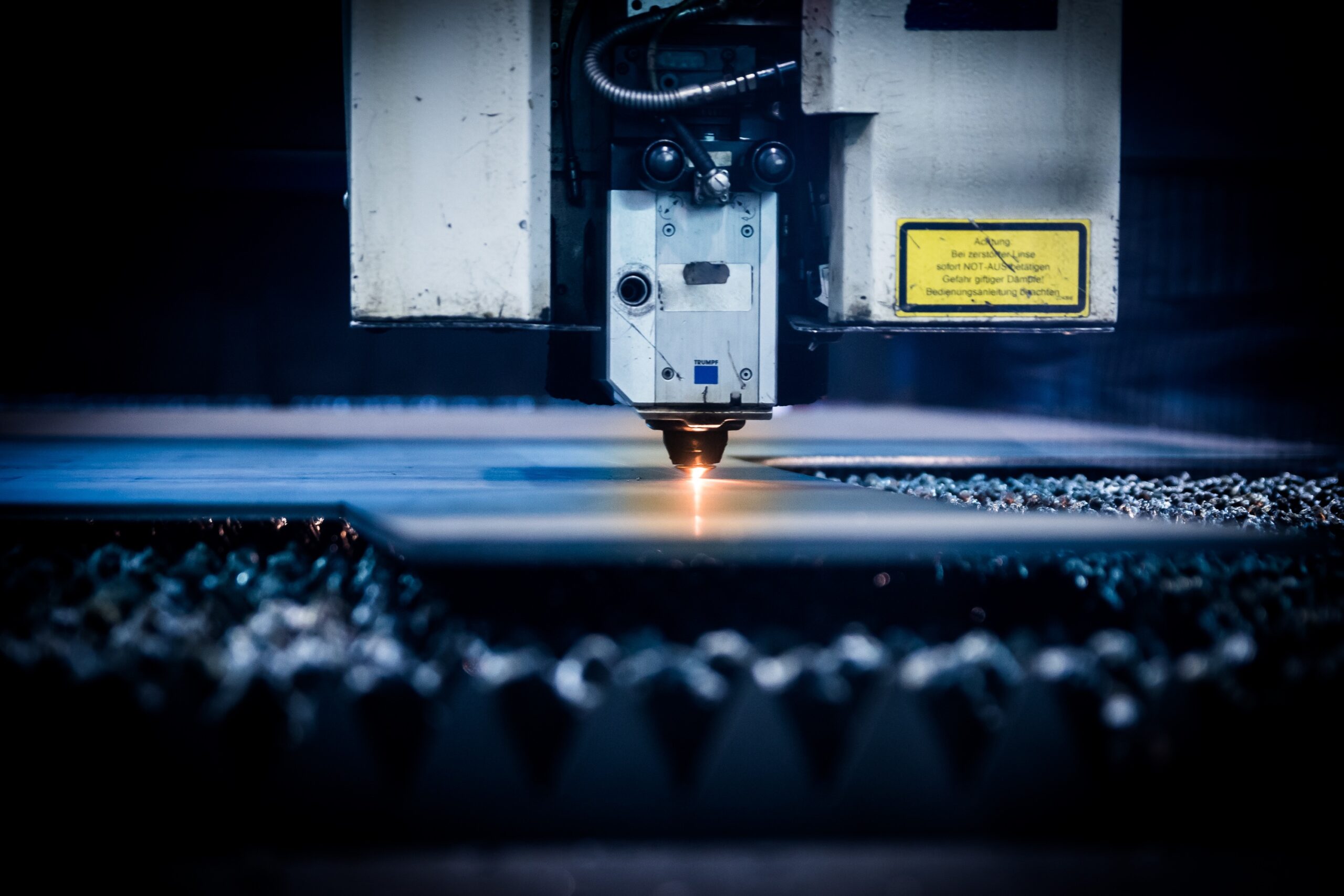

A CNC laser reducing device is primarily a CNC fiber laser cutter that utilizes CO2/fiber laser resource to rapidly cut steel and various other non-metals products into lots of different forms. A fiber handheld laser engraver laser cutter has numerous benefits over a typical laser etching laser for example, the laser made use of in a fiber laser cutter can be differed in wavelengths of light that the laser brightens, therefore developing several various shades.

A CNC fiber laser cutter has many attributes that assist to lower the moment called for to produce a premium quality cut. Among the first and finest attributes of this sort of laser engraver is that it is fairly affordable. While the price might seem like a significant offer when you contrast them to laser inscription laser makers, it is really much cheaper than traditional laser engraving devices. A few of the significant advantages of utilizing a fiber laser cutter include:

- Cost: A CNC fiber laser cutter is usually a lot less expensive than a traditional laser engraver. Many individuals find these types of equipments to be more budget-friendly than engraving laser devices when you take into consideration the quantity of energy that can be put into each laser beam of light. This aids to allow customers to develop a better variety of reducing shapes.

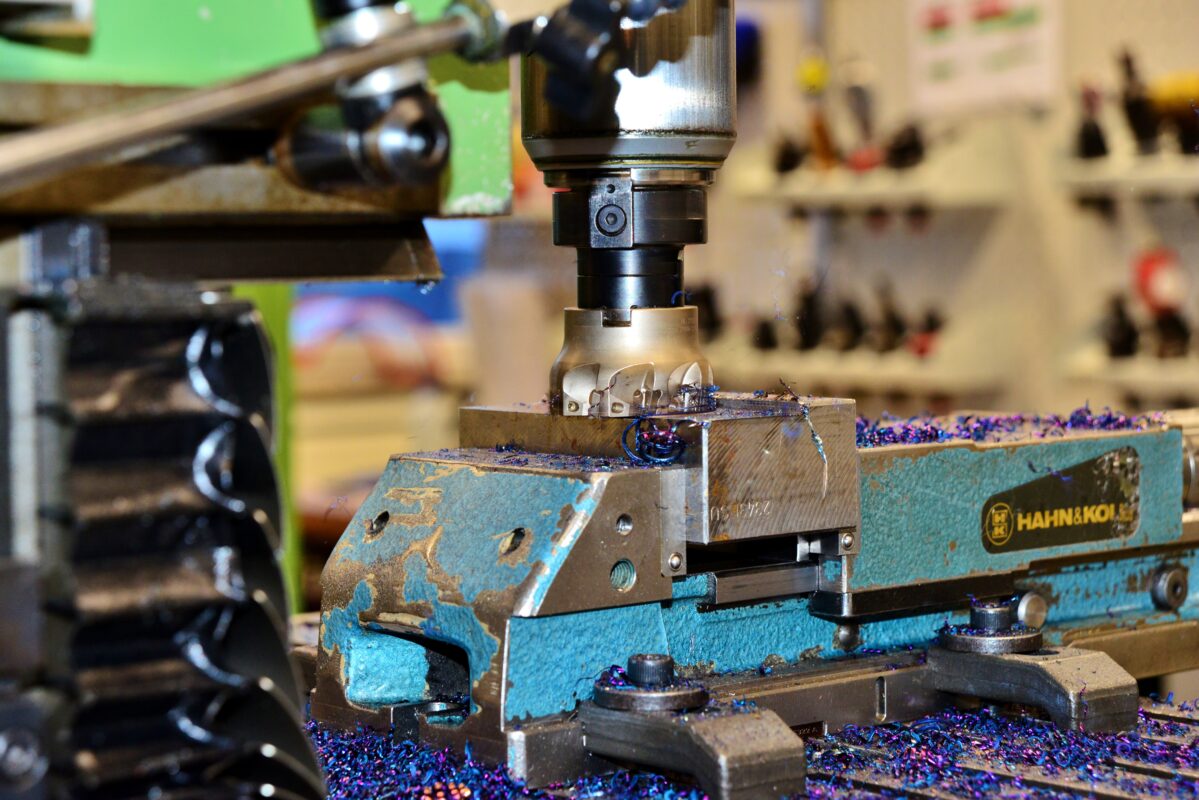

- Laser Accuracy: While the fiber laser cuts material at a faster price than conventional laser modern technology, a high quality cut can still be achieved. An excellent fiber laser cutter can also generate comprehensive cuts that need less manual job than a typical laser engraver.

- Toughness: Some fiber lasers are created to be used on a constant basis, while various other sorts of lasers are limited to run only throughout the production of a product or various other job. This means that some lasers can not carry out along with those that can be used on a hourly basis. The kind of laser you will certainly need to purchase relies on the degree of performance you are seeking.

- Precision: When utilizing a laser engraver device, the outcome can be specific and also regular. When acquiring a fiber laser cutter equipment, make sure you pick one that supplies premium quality outcomes and a wide variety of shades. These machines also provide greater rates, which can aid to create an excellent quality cut in a much shorter amount of time.

- Speed: Among the greatest factors to purchase a CNC equipment is as a result of its ease of operation. As a result of this feature, a laser cutter can swiftly be utilized to generate a number of different cuts in a shorter period of time. If a high quality outcome is wanted, a high degree of accuracy is important.

- Top quality: There are several types of lasers available for a selection of applications. When searching for a laser cutter equipment, make certain that you select a device that uses a high level of quality for the amount of time as well as cash that you will certainly be putting into the task.

- Expense: Given that laser innovation has actually been established over the past few years, it is simple to find a top quality CNC equipment at a cost that will fulfill your requirements. While there is a selection of prices readily available for fiber laser equipments, they are usually more economical to run than fiber lasers.

- Sturdiness: CNC laser cutting equipments can be operated by the majority of people. This means that a driver must not need to be qualified to run the tools. Instead, a person who wishes to utilize a laser cutter need to be able to find out just how to make use of the machine and also use it quickly. Lots of kinds of laser devices will feature guidelines and a video clip on exactly how to operate them.

Regardless of what type of laser you pick to purchase, it is essential to think about these elements when acquiring a CNC laser cutting equipment. When selecting your laser cutter, make certain to take into consideration the amount of time as well as cash you will be spending in order to get a good quality result.

A CNC laser cutting device is essentially a CNC fiber laser cutter that uses CO2/fiber laser resource to swiftly cut steel hobby metal laser cutter and also various other non-metals products right into several various forms. A fiber laser cutter has lots of benefits over a standard laser engraving laser for example, the laser utilized in a fiber laser cutter can be varied in wavelengths of light that the laser illuminates, thus fiber laser engraver producing many various shades. While the cost might appear like a significant bargain when you contrast them to laser engraving laser equipments, it is really much less costly than typical laser inscribing equipments. Many people find these kinds of machines to be even more cost reliable than etching laser makers when you take into consideration the amount of power that can be placed right into each laser beam.- Laser Accuracy: While the fiber laser cuts product at a quicker rate than standard laser innovation, a high quality cut can still be attained.

Log in with Facebook

Log in with Facebook