Bending a metal sheet is a pretty difficult task and as a fabricator, you might know just how challenging it is. But there are press brakes now. They have definitely made this task a little less difficult.

Being a proud owner of press brake, you might know the details of its evolution.

No?

Don’t worry, because we are going to talk about just that in this article. The evolution of press brake machines.

Technology advancements have brought immense growth and expansion for every industry. Be it automotive, travel, education, metal fabrication, you name it; technology is there.

Digitalizing the automotive industry has helped companies to increase competitiveness among themselves. Additionally, it is even enhancing customer satisfaction and provides them with an excellent quality of service.

Similarly, in education, digitalization helps in making sure that education reaches everyone. Not only this but online learning also benefits people a lot as it makes knowledge easily accessible.

But we are here to talk about digitalization of the metal fabrication industry.

So, let’s look at how the evolution of technology provides ease to a fabricator.

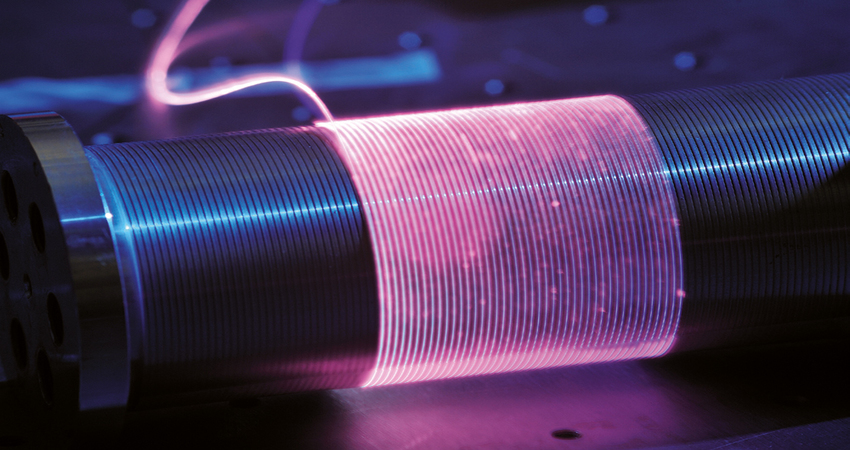

Fabrication technology plays a vital role in changing the metal forming and welding. One tool which has changed a lot is Press Brake. Do you remember the time when you would bend sheets using manual press brake and how difficult it would be? Now there are hydraulic or electric press brakes that increase productivity and decrease costs.

So, let’s see how they evolved and where we stand with press brakes today.

This evolution of press brakes took place in three parts:

- Drive Systems

- Automation

- Coordinated Flow

In this article, we will explore the evolution of drive systems and automation which led to invention portal press brakes.

1. Drive Systems

In the early 1960s, there was mechanical press brake. The system had a motor with clutch, flywheel, eccentric crank and brake and can generate only 30 strokes per minute.

The mechanical press was popular for sheet metal industry’s mass production for a long time but then the needs were changing which, in turn, led to changes in press brakes.

By the time production became the new craze in metal fabrication, fabricators demanded their machines to be flexible in function and to have better capabilities to create custom products for consumers in a short time.

The change in consumer production led to the development of hydraulic press brake. It had controls for ram speeds, stroke lengths, applied force, and angle controls. Despite the slow pace, these brakes were useful until electric press brakes replaced them.

The introduction of the electric press brake was needed because of high demands, needs and constant change from customers’ behavior. It helped in increasing production speed for fabricators.

The electric press brake and the hybrid hydraulic electric drives have the approach speeds of 700 inches per minute (IPM) and bending speed as low as 5 inches per minute (IPM).

The different capabilities of these machines permit better functioning, efficiency, and precision in every bend.

2. Automation

The Industrial Revolution went on for over 150 years and played a vital role in the way we see manufacturing.

Before, press brake operators spent a large amount of time in programming, test bending, inspecting and adjusting the products and machines.

Current press brakes can perform accurate measurements and solve angular errors if any. It offers precise bending and better customization without you having to pay a lot of attention. All thanks to technology and parts like Mitsubishi laser parts and Mazak laser parts.

This revolution has improved the storage and the use of computer programs has made it easy to design and setup machines. It also helps in speeding up the designing process making the fabrication process faster and precise.

3. Ease of Use

Portable press brake comes with improved speed and makes the fabrication process easy. These machines are smaller and occupy little space in shops. Their size makes it easy to transport and use it.

Regardless of the fabrication project, the usage of press brake allows work to finish with less production time and ease. Once the sheets are ready, they are cut into sizable sheets using laser cutting with parts like Mitsubishi laser parts and Mazak laser parts.

Wrapping it up:

Digitalization has always helped mankind. Be it in automobiles, education, fabrication industry, etc. It brings ease to human life. The technology revolution which happened in the fabrication industry made the bending of materials and lives of fabricators easier. Apart from technology, quality parts like Mitsubishi laser parts and Mazak laser parts have also played a vital role in the improvement of press brakes.

Log in with Facebook

Log in with Facebook