Table of ContentsEverything About Liquid RoofsTypes Of Liquid Applied Roof Waterproofing SystemsRoof Problem Areas Addressed By Liquid Roofing MaterialsCold Liquid-applied RoofingLiquid Roofing - Answering Your Questions

Consist of membranes that are set up "in place" using extremely long lasting, water based, waterproofing compounds enhanced with difficult polyester materials and surfaced with energy conserving reflective finishings. Once installed the seamless monolithic system is hard, flexible and resistant to the extremes of nature. We use Underwriters Laboratories (U.L.), FM Worldwide and independent testing labs to continuously test our Systems and Products to be sure they meet the rigid requirements these days's building market.

Western Colloid's Fluid Applied System's lead to a seamless surface making future evaluations and upkeep easy. It likewise means the roofing can be resurfaced, therefore extending the life of the roofing forever. Western Colloid's FARR system's can be applied over BUR, Modified Bitumen, Single Ply, Metal Roof, Sprayed Polyurethane Foam and Gravel roofing systems.

Save money on energy and devices costs (starting right away after the roof is installed). Indefinitely extend or remove your need to re-roof or deal with major repair work. Can be used over your existing roof with really little trouble. Will not affect employee/tenant efficiency due to fumes. Can be shipped wholesale to the task website via our big fleet of tankers.

Liquid Applied Roofing Products

No toxic fumes or fire risk. Every product is backed by experience and efficiency. A number of our FARR systems have actually gotten UL Class A ratings. "Class A" roofing system assemblies have the best fire resistance. Furthermore, much of our systems have actually also gotten FM 4470 Class 1 approval. To achieve this designation, the system undergoes laborious screening for fire, hail damage, water leakage, and resistance to foot traffic.

Throughout the middle of the 19th century, contemporary roof as we understand it started to take shape when rag felt soaked in tar was layered with hot-mopped tar and covered with gravel. In time, the tar was mostly change by asphalt and the rag felt by fiberglass mat to produce the modern-day built-up roofing system (BUR).

Fluid-applied Roofing Systems Brochure

Fluid-applied Roofing Systems Brochure

According to Jason Smith, senior R&D chemist at the Garland Business, cold-applied roof systems refer to roofing systems that are adhered with an adhesive that doesn't require to be warmed prior to its application. They are utilized best out of the drum or pail and used utilizing a notched squeegee, or also by brush, spray, or roller, depending upon the viscosity of the product.

Liquid-applied Waterproofing Roofing Products

Lee Martucci, product supervisor at GAF, keeps in mind, "The innovation was developed as a method to counter concerns over possibly hazardous hot asphalt and fumes. When installing a roofing without the big, unpleasant hot kettles and fumes, the environmental and health issues from the pubic minimize. Plus, professionals can install the membrane systems without purchasing pricey kettles: all they require is a squeegee." Cold-applied roofing eliminates unpleasant hot tar kettles and the associated fumes, which develops a safer jobsite and less irritation for the building residents.

George Daisey, a research researcher at Dow Chemical Company, points out that cold-applied roof setups enable more secure handling of materials, as there is no hot container to be hoisted onto the roof. Likewise, the application process removes the potential for burns or respiratory inflammation from hot fumes. Overall, cold-applied roofing systems result in a lower level of odor at the job website, which Martucci suggests can lead to less grievances from building occupants.

With much less equipment needed than in a hot-applied roof job, the general equipment costs are significantly lower. Smith, at Garland, explains that cold-applied roofing system systems can be created to have lower volatile natural compound (VOC) emissions, which can be of significance in VOC-restricted areas like California and much of the northeastern U.S.

Paints, Coatings, Liquid-applied Membranes In Roofing

Liquid Applied Roofing Solutions

Liquid Applied Roofing Solutions

According to Daisey, the term "cold-applied roof system" was originally utilized to describe a solvent-based built-up roofing system that did not need heat to install. Today, the term has actually expanded considerably as a range of innovations have actually been developed to encompass the range of roof that do not need heating to be installed.

Cold-Process Built-Up Roofing uses heavyweight asphalt-impregnated fiberglass base how much does it cost to repair roof leak sheets adhere in multiple plies with solvent-borne asphalt adhesives. The very first sheet is usually mechanically connected to the substrate (typically insulation) and subsequent plies (normally 3 or four total) are embedded in an application of adhesive at a rate typically between 1.5 and 2.5 gallons per 100 sq.

Cold-process BUR uses solvent-based asphalt adhesives to adhere numerous layers of base sheet without heat. The membrane is then covered with aggregate. As soon as the waterproofing layer remains in location, the membrane is covered with an aggregate surface area or roof finishing. Modified Bitumen Roof is an adaptation of "torch-down" roofing. Customized bitumen roofs were traditionally set up utilizing a gas torch to melt the back of the sheet, developing a molten adhesive in which the roll might be embedded.

Liquid Applied Rubber Roofing Systems

For obvious security reasons, https://blogfreely.net/agnathaeo0/b-table-of-contents-b-a use of cold-applied roof has provided an attractive alternative to making use of hot asphalt or open flame. These roofing systems generally have a mechanically connected base sheet, and one or two plies of modified bitumen membrane installed in bituminous adhesives. Smith explains these adhesives as "rubber-modified how much to fix shingles on roof fibered solvated asphalt adhesives that dry via solvent evaporation." Martucci includes, "These buildings usually include asphalt/solvent blends used by a squeegee to adhere the membranes to the substrate of other membranes, although there are other technologies that can be used.

Monolithic Liquid-Applied Roof blurs the line between roofing system covering and roofing system membrane system. Normally made from state-of-the-art polymeric resins such as urethanes, these roofing systems are used as a liquid and typically require no strengthening material, treating to a hard, rubber-like membrane. (See sidebar listed below). Naturally, as is the case with all roof innovations, there are specific downsides to utilizing cold-applied roofing system systems.

https://www.youtube.com/embed/MrQEQcrjwFI

Liquid-Applied Roofing is used as a liquid and often needs no enhancing product, curing to a difficult, rubber-like membrane. Extra considerations consist of the flammability of cold-applied adhesives that are made with solvated asphalt, in addition to the potential for solvent odor to penetrate through occupied spaces via vents, just as with the smells from hot-applied roofing systems.

Log in with Facebook

Log in with Facebook

Silicone And Acrylic Roof Coatings

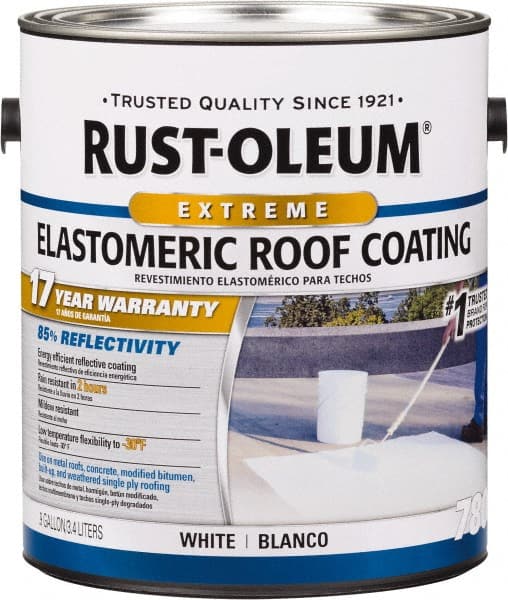

Silicone And Acrylic Roof Coatings Elastomeric Roof Coating Contractors Battle Creek

Elastomeric Roof Coating Contractors Battle Creek What Is An Elastomeric Roof Coating?

What Is An Elastomeric Roof Coating? What Is Liquid-applied Flashing

What Is Liquid-applied Flashing What Is Liquid-applied Flashing

What Is Liquid-applied Flashing Product Evaluation

Product Evaluation What Is & How To Apply Elastomeric Roof Coating

What Is & How To Apply Elastomeric Roof Coating Duck Coat Roof Coating – Duck Coat

Duck Coat Roof Coating – Duck Coat