Augmented reality is the technology that allows us to overlay digital information on the physical world. Unlike virtual reality, which creates an entirely new environment, augmented reality uses the existing environment and overlays computer-generated information on our view of it. Augmented reality works by photographing a person or object and placing that image in a computer-generated context (such as a soccer field), making it appear as if there was no camera present when the picture was taken.

Helps in reducing cycle time

The most obvious benefit of augmented reality companies is that it allows you to see the physical world with the help of virtual objects. This can be useful for monitoring and tracking a manufacturing process. For example, if you want to know how much time it takes for your workers to complete a particular task, then all you have to do is use a camera or wearable device and then overlay information about their actions on top of the video feed they are recording.

As we already mentioned earlier in this article, augmented reality can also be used by managers who wish to monitor their employees' performance and efficiency levels throughout the day. While traditional cameras allow managers to only take snapshots of production lines at given periods during each shift, AR technology lets them watch live footage which gives them more flexibility in terms of being able to perform accurate assessments of production activities at any point in time.

Increase efficiency

One of the major benefits of using augmented reality in manufacturing is that it helps in increasing efficiency. This is because when a worker uses an AR headset, they can get a 3D view of an assembly line and see how each process works before actually starting to work on it. This way, there are no mistakes as everything is pre-visualized and planned out, saving time and reducing human error and cost.

Quality control

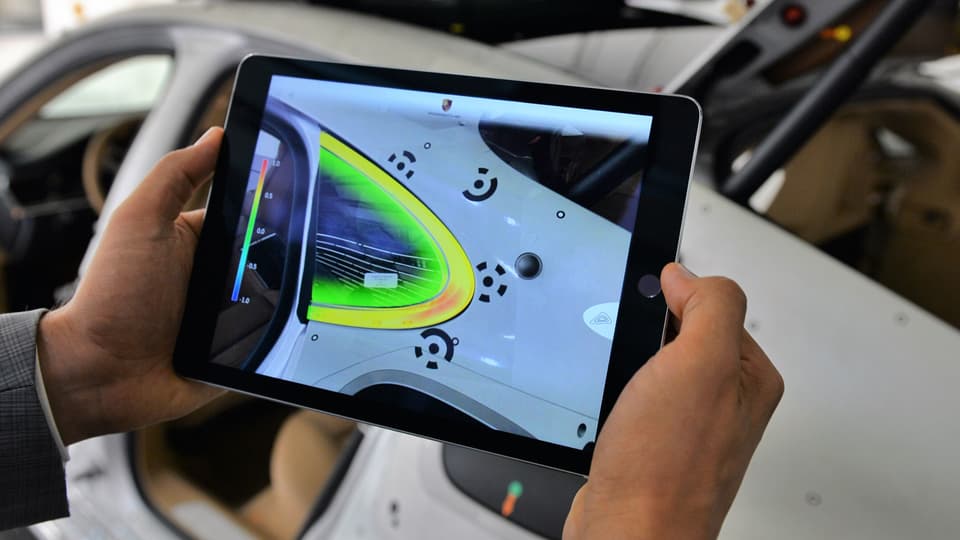

One of the major benefits of Augmented Reality technology is that it helps in improving the quality of products and services. In the manufacturing industry, this technology can be used to identify defects and improve quality by identifying their root cause.

This will result in improved quality of products and services while reducing costs at the same time. Additionally, it will also help in optimising processes, leading to increased productivity, efficiency, and profitability for companies that use this technology for quality control purposes.

Augmented reality helps in improving the quality of products and services.

It helps to improve the efficiency of manufacturing processes, reduce the cycle time of manufacturing processes, improve the efficiency of manufacturing processes, and improve the quality of manufacturing processes.

Conclusion

There are many ways in which augmented reality companies can be used to improve the manufacturing process. The best thing about this technology is it will not only save time but also reduce waste as well as cost.

Source: How Augmented Reality Helps In Manufacturing Industry?

Log in with Facebook

Log in with Facebook